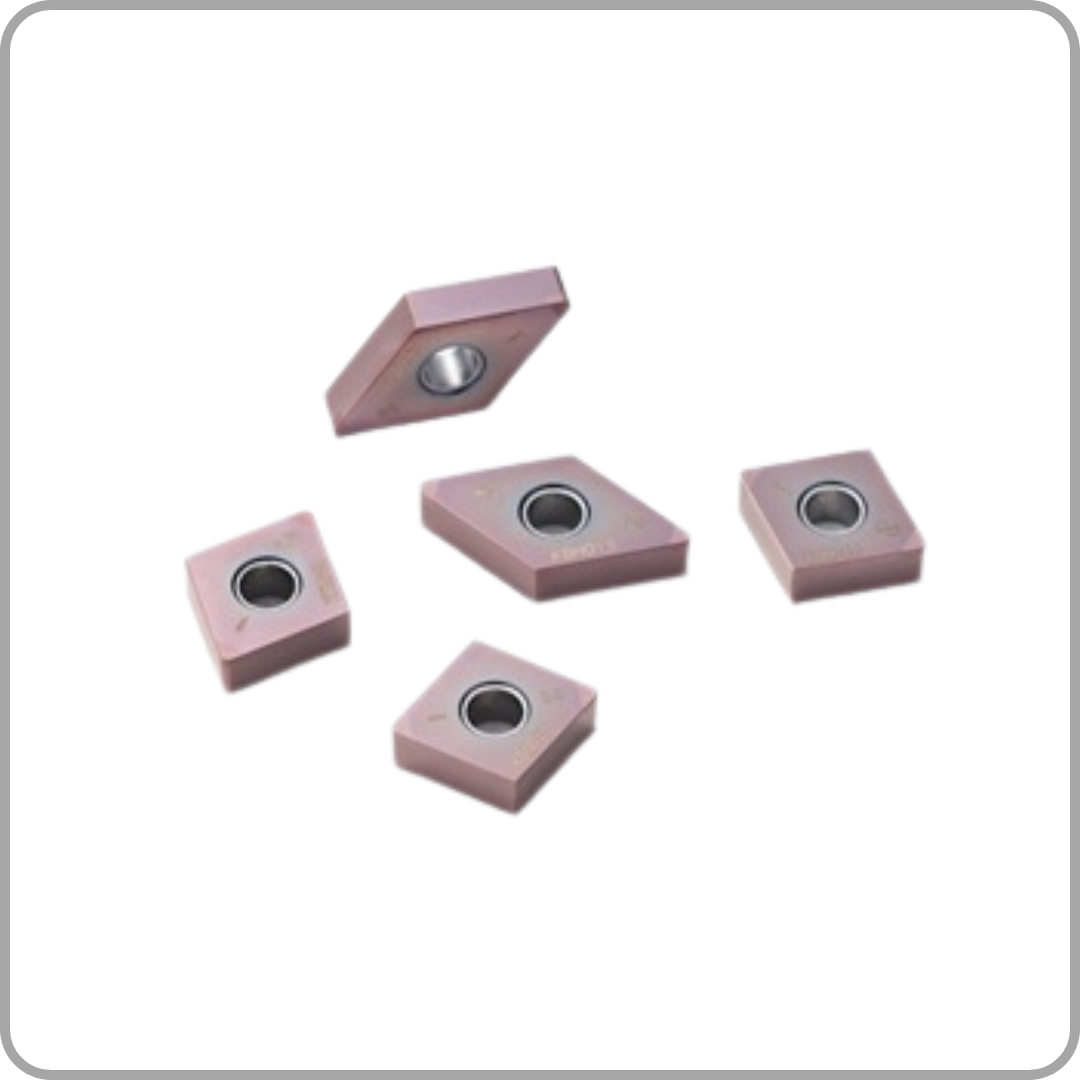

Deskripsi

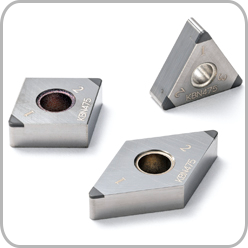

KBN015 is a new-generation coated Cubic Boron Nitride (CBN) insert developed by Kyocera for high-performance machining of hardened steel, typically in the range of HRC 55–65. Engineered for superior wear resistance, thermal stability, and surface finish, KBN015 is ideal for continuous to light interrupted cutting applications such as finish turning of die steels, tool steels, and carburized parts.

The advanced multilayer TiCN + Al2O3 coating enhances performance by protecting the CBN substrate from oxidation and wear, thereby extending tool life and maintaining dimensional accuracy over longer cycles.

-

Excellent wear resistance for high-hardness steel machining (HRC55–65)

-

Multilayer coating (TiCN + Al₂O₃) for heat and oxidation resistance

-

Tough CBN substrate for stability in light interrupted cutting

-

Superior surface finish and dimensional control

-

Optimized for finishing to medium finishing operations

-

Stable edge strength for consistent performance

| Property | Detail |

|---|---|

| Grade | KBN015 |

| Material | Coated Cubic Boron Nitride (CBN) |

| Coating | TiCN + Al₂O₃ |

| Application Range | Hardened Steel (HRC55–65) |

| Machining Type | Finish to Light Interrupted Cutting |

| Cutting Speed (vc) | 100 – 250 m/min (depending on application) |

| Feed Rate (fn) | 0.05 – 0.3 mm/rev |

| Depth of Cut (ap) | 0.1 – 0.3 mm (typical) |

| Recommended Coolant | Dry Cutting (preferred) |

Typical Applications:

-

Finish turning of carburized steel gears and shafts

-

Precision machining of die and mold components

-

Bearing surfaces of hardened mechanical parts