Description

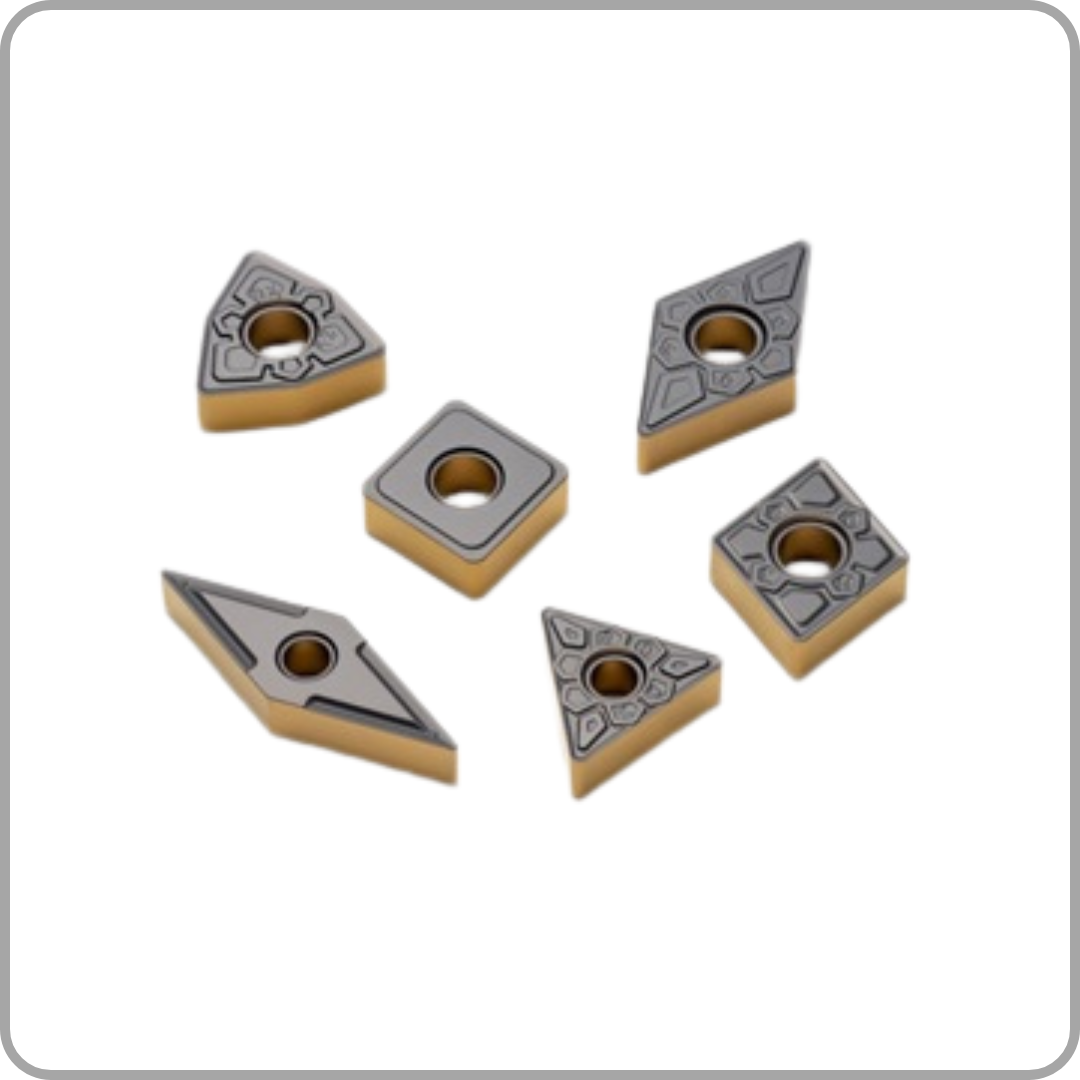

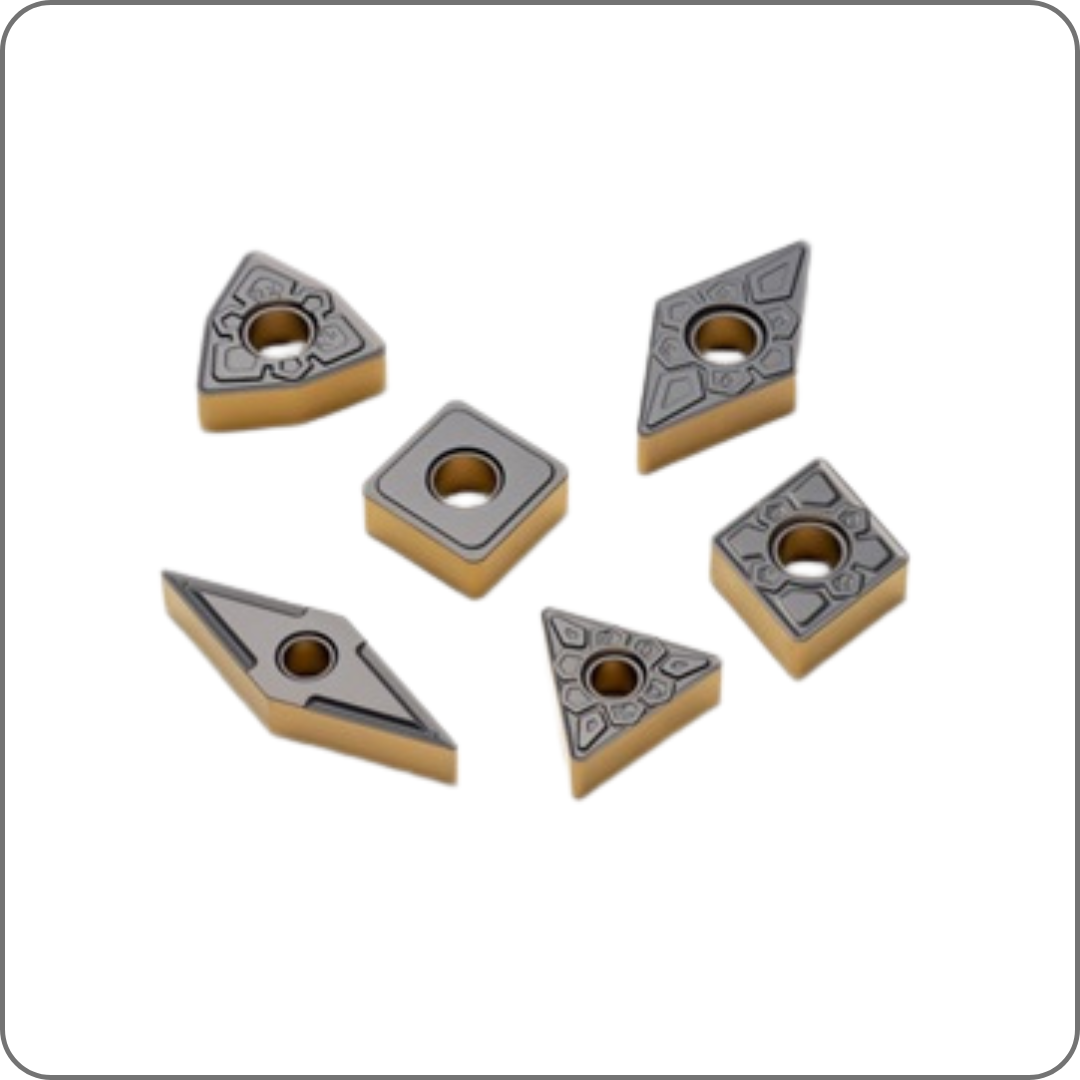

Kyocera CA410K and CA415K are premium CVD coated carbide grades developed for high-efficiency machining of cast iron (both grey and ductile types). These grades offer a combination of exceptional wear resistance, thermal stability, and edge strength, ensuring longer tool life and stable cutting performance even under harsh conditions.

Both grades feature a multi-layer CVD coating optimized for cast iron applications, helping prevent crater wear and built-up edge while improving heat resistance and surface finish quality.

| Grade | Application | Coating Type | Coating Material | Workpiece Material | Cutting Type | Hardness (HRA) | Wear Resistance | Toughness |

|---|---|---|---|---|---|---|---|---|

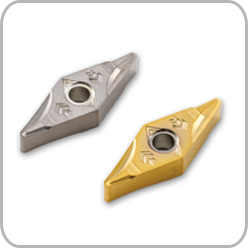

| CA410K | Finishing / High-speed | CVD | TiCN + Al₂O₃ | Grey Cast Iron (FC) | High-speed finishing cuts | ~92 HRA | ★★★★★ | ★★★☆☆ |

| CA415K | General purpose | CVD | TiCN + Al₂O₃ + special surface treatment | Grey & Ductile Iron (FC/FCD) | Roughing to Semi-finishing | ~91 HRA | ★★★★☆ | ★★★★☆ |

Key Features:

CA410K:

-

Optimized for high-speed finishing of grey cast iron.

-

Excellent resistance to flank wear and oxidation at high temperatures.

-

Ideal for dry machining.

-

Surface treatment reduces built-up edge, ensuring smooth surface finish

CA415K:

-

Tougher grade suitable for a wide range of cast iron types (FC/FCD).

-

Improved fracture resistance for stable roughing or semi-finishing.

-

Handles interrupted cuts and moderate cutting loads well.

-

Strong balance of wear resistance and edge toughness.